In the bustling world of warehouses and engineering facilities, forklifts provide unparalleled efficiency, facilitating the movement of heavy loads. However, forklifts do not come without inherent risks that operators must manage to prevent accidents or injuries. Our comprehensive blog will shed light on the common incidents, from minor mishaps to severe accidents, that can occur when operating a forklift and how you can use a forklift safely to ensure your safety and the well-being of those around you.

- How Many Forklift Accidents Occur Per Year

- Dangers of a Forklift

- Common Forklift Accidents

- Measures to Prevent Forklift Incidents

- Forklift Dangers FAQs

How Many Forklift Accidents Occur Per Year?

Many drivers do not understand the dangers associated with driving a forklift; any incidents that occur put the driver and those surrounding the forklift at risk.

Each year, there are numerous forklift-related accidents. In 2022/2023, there were 135 work-related fatalities, with 30% falling from a height and 15% being struck by a moving vehicle such as a forklift, according to the Health and Safety Executive (HSE).

Dangers of a Forklift

Weight Distribution

Forklifts can be unstable due to their uneven weight distribution. Due to this, forklifts can tip or fall over when they are overloaded or making sharp turns. On average, forklifts weigh 4080 kilograms, around 3x the weight of a standard car, so being hit by a moving forklift will cause severe injury and may even be fatal.

Unstable Load

In cases where a forklift is overloaded, or the weight is not evenly distributed, it becomes challenging to drive safely. The load is at a higher risk of falling off when picked up or out down, primarily when carried in a raised position. A heavy load falling can cause significant damage to the load and potentially injure a passer-by.

Stopping Distance

Forklifts have a longer stopping distance than most operators realise. A standard forklift will travel at least 51 feet before stopping if it moves at 9 mph. Due to this, an operator may be unable to stop in time to prevent a collision with a wall, an object, or a person.

Restricted View

When a driver has an overloaded forklift in which their view is obstructed, it can be difficult to operate safely. The load can block their view, making it more difficult to avoid obstacles such as objects or people in their blind spots.

Common Forklift Accidents

Unfortunately, forklift incidents are common; below are the most frequent accidents:

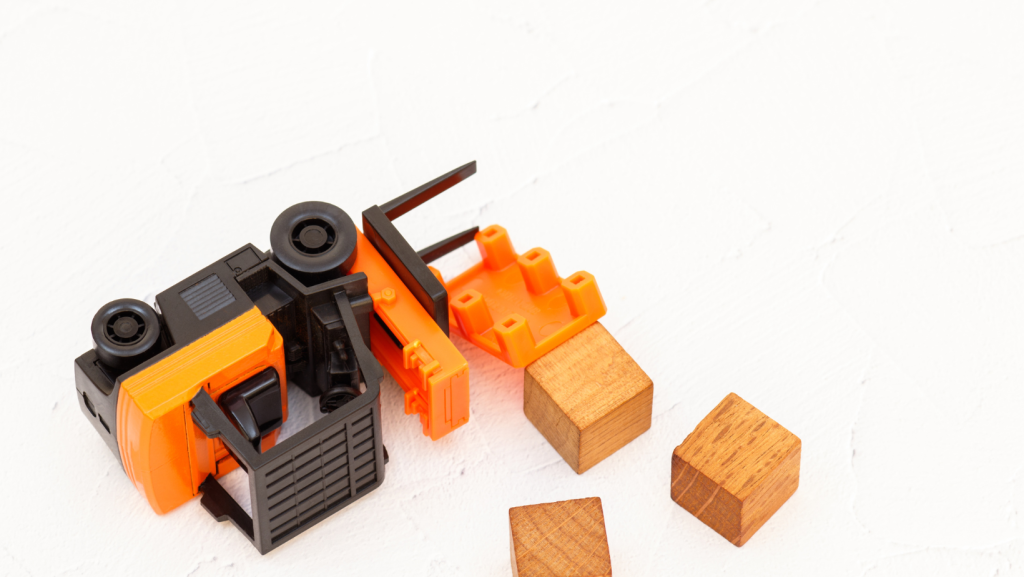

Forklift Tipovers

A falling forklift is the most common accident with the highest fatality rate. Rollovers can be caused by numerous factors, notably turning sharp corners too quickly, carrying an uneven load, driving on uneven surfaces, exceeding your lift capacity, and making abrupt movements. Any of these will increase the chance of a forklift tipping over, harming the driver and surrounding individuals.

Colliding with a Pedestrian

One of the other common types of forklift accidents involves colliding with pedestrians. Unclear boundaries within a warehouse mean that pedestrians and operators may cross paths unexpectedly, resulting in an accident. Operator fatigue and carelessness increase the risk of pedestrian crashes, leading to injury or death.

Falling Loads

In 2022/2023, 20 deaths in the UK occurred when a pedestrian was struck by a falling load. Many forklift jobs require operators to lift and drive unstable loads. Operators must take all preventive measures, such as securing a load to the forks to prevent injuries and fatalities. Bent forks combined with uneven, loosely secured loads are more likely to result in a falling load.

Riding the Forks

It is advised never to stand on the forklift’s forks, especially in the elevated position. While using a forklift to reach heights is tempting, other equipment, such as MEWPs, provides a safe option for reaching heights. Incidents that occur when personnel ride the forks include head trauma, internal bleeding, and impalement.

Crushing of Pedestrians

Crushing hazards are also one of the top causes of forklift accidents and fatalities. In cases where an operator reverses without checking their surroundings properly or has not secured their load properly, pedestrians can be crushed between the forklift and a fixed object. If a pedestrian is pinned and cannot escape, they could face severe injuries with fatal results.

Measures to Prevent Forklift Incidents

According to the Occupational Health and Safety Association (OHSA), up to 70% of forklift incidents are preventable. Several measures can be put in place to minimise the number of forklift accidents in the workplace.

Operator Training

Forklift safety is critical; equipping operators with the knowledge and skills to handle and drive a forklift safely will reduce incidents. Whether you are a novice or have operated a forklift for years, courses are available to ensure that your operating skills are up to scratch. A forklift licence does not exist; however, employers will request that all operators are fully trained to operate a forklift safely.

Warehouse Zoning

Exclusion zones should be incorporated into any warehouse or facility where a forklift will be driven. These zones highlight where forklifts will operate, warning pedestrians to be alert while in this area or to keep away altogether. Barriers and cones should be used to define these zones.

Routine Maintenance Checks

Pre-shift operators should check their forklifts to ensure everything is working. Any issues should be immediately flagged, and necessary repairs should be carried out before using the forklift. Issues related to the forklift’s function can lead to an accident; services should be carried out every 6 months to prevent accidents.

Secure Loads

Forklift loads should not exceed lift capacity; an unstable load is more likely to cause an injury to the operator or others around the forklift. Larger loads should be secured with ropes or bands to prevent them from slipping especially when turning corners. Loads should not restrict the operator’s view; an evenly distributed load maximises safety.

Driving Rests

Operators tend to carry out long shifts of 12 hours. To prevent accidents from fatigue, operators should take frequent breaks from driving the forklift to ensure that when operating one, they are in the best frame of mind to drive safely and prevent accidents.

Stick to Speed Limits

While indoors, forklifts should not be operated at more than 10 kph. Sticking to the maximum speed limit will ensure that when an operator moves a heavy load, it is less likely to move or fall off, especially when driving on uneven surfaces. Driving steadily and checking blind spots will enhance the safety of the operator and the pedestrians surrounding.

Forklift Dangers FAQs

How many forklift deaths occur per year?

On average, as reported in 2021, there were 27 deaths a year resulting from forklift incidents in the workplace. The most common nature of fatality was due to the overturning of a forklift.

What should you do if the forklift starts to tip?

Protect yourself if your forklift starts tipping by staying in your seat and leaning away from the falling direction of the forklift. Hold onto the steering wheel for added stability, and refrain from trying to jump off, as you may injure yourself further.

What not to do on a forklift?

Do not overload your forks. Don’t travel at speed when making directional changes. Avoid driving on uneven surfaces, especially when wet or slippery. Never climb or ride on elevated forks.

Prevent Forklift Accidents with HL Training

At HL Training, we have years of experience dealing with forklifts and are incredibly aware of all the dangers associated with operating in and around a forklift. Our team can provide you with the essential tips and tricks so that you can effectively handle a forklift to minimise any accidents or injuries in the workplace. We offer both on-site and in-centre training for operators and instructors nationwide. Boost the forklift safety in your warehouse today and enrol in one of our training courses.